Engine idling in Nigerian fleets seems harmless, but it is one of the most expensive and overlooked issues in transport and logistics. Every day, vehicles waste fuel, reduce engine life, and lose valuable productivity simply because the engine is left running while the vehicle is not moving. Although many drivers believe it is a normal practice, the hidden cost continues to grow.

Engine idling wastes fuel quickly

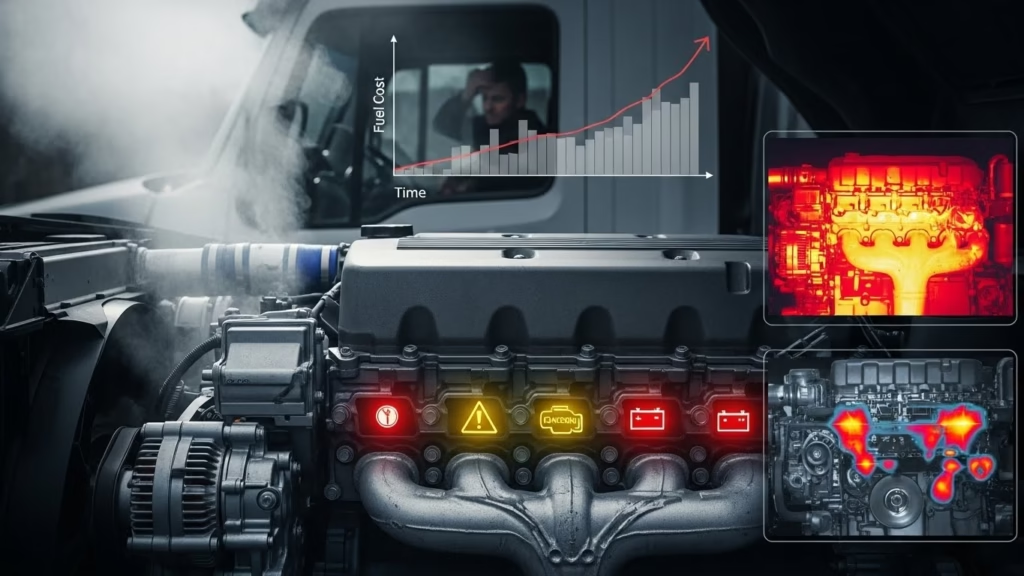

When a vehicle idles, it burns fuel without covering any distance. Some engines can consume between one and two litres of fuel every hour while idling. As a result, fleets spend money without gaining any operational benefit. For example, a fleet of twenty vehicles idling for only thirty minutes every day can waste up to two hundred litres of fuel every month. This waste reduces profit and increases operational stress.

Idling also damages the engine over time

Although an idling engine sounds calm, it is under quiet internal stress. It experiences incomplete combustion, carbon buildup, and faster wear on plugs and pistons. Over time, this leads to more repairs, more downtime, and more money spent on maintenance. Because of this, fleet owners end up paying significantly more than they realize.

Nigeria’s transport environment encourages idling

Several everyday situations in Nigeria make idling common. Traffic gridlock forces vehicles to stay in place for long periods. Security checkpoints often require drivers to wait. Loading and offloading can also take time. In addition, the heat encourages drivers to leave the engine running so they can use the air conditioner. While these conditions are understandable, they increase fuel consumption and engine wear.

Idling reduces productivity

Every minute a vehicle is idling is a minute lost in productivity. This affects the number of trips completed each day and reduces efficiency. It also affects delivery times, customer satisfaction, and overall business performance. In many cases, it creates the false impression that drivers had a long workday when much of the time was spent waiting.

How to reduce engine idling in Nigerian fleets

Fortunately, reducing idling is achievable. With the right approach, fleets can save fuel, lower costs, and improve vehicle lifespan.

Introduce a simple idling policy

First, establish a clear policy that encourages drivers to switch off the engine after two minutes of waiting unless there is a safety concern. A simple rule like this helps drivers understand expectations.

Use telematics to monitor idle time

Telematics systems help fleet managers identify idle patterns. This information shows which routes cause long waits, which drivers idle the most, and what time of day creates delays. With this data, managers can make better operational decisions.

Train drivers regularly

Many drivers do not know how much idling costs the company. By explaining the financial and technical impact of idling, drivers become more mindful. Regular training leads to better habits and reduced waste.

Improve route and trip planning

Better planning helps reduce long waiting times at checkpoints or congested roads. When drivers follow optimized routes, they spend less time stuck and less time idling.

Address comfort needs

Some drivers idle the engine because they need the air conditioner. Providing shade during loading or optimizing delivery times helps reduce this need. Small adjustments can make a big difference.

Reducing idling offers instant savings

Cutting idling is one of the fastest ways for Nigerian fleets to reduce fuel cost and extend vehicle life. It does not require new vehicles or heavy investments. It simply requires awareness, monitoring, and consistent habits.

As Nigeria continues to face rising operational costs, reducing engine idling in Nigerian fleets becomes essential. The fleets that act now will operate more efficiently, save more money, and stay competitive in the long term.