Fleet maintenance for businesses reliant upon vehicles is much more than a routine undertaking. Unexpected breakdowns, high repair bills, and vehicle downtime disrupt operations and hurt profits. Traditional methods of maintenance all too often fall short since they react to a problem rather than prevent one.

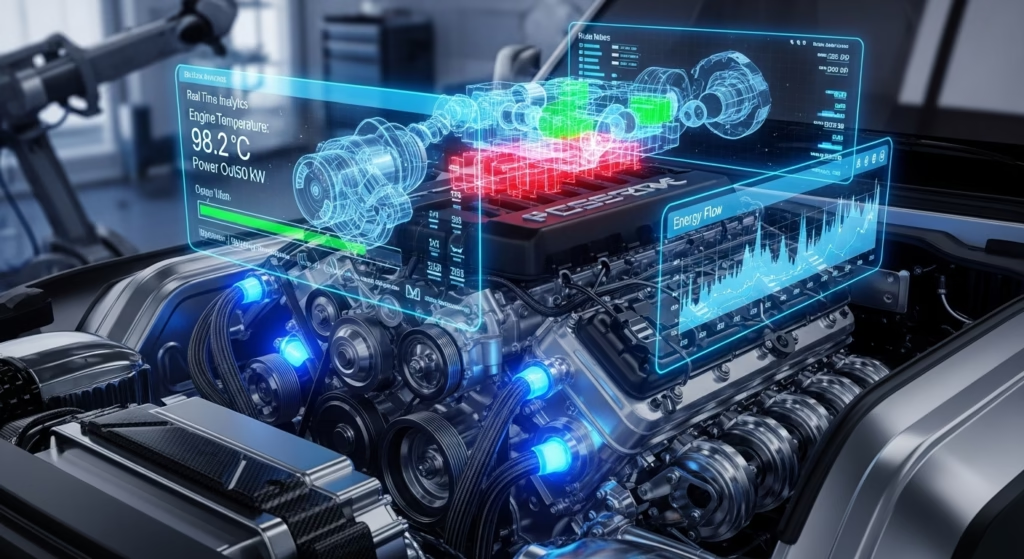

Predictive maintenance is changing the game: using real-time data, sensors, and analytics, firms can detect potential vehicle issues before they become expensive problems. All this makes operations more efficient, saves cash, and keeps drivers and cargo safe.

What is Predictive Maintenance?

Predictive maintenance is a proactive approach in which potential mechanical issues are determined by computer-driven data. On vehicles, sensors monitor engine performance, fluid levels, brake conditions, tire pressure, and other critical metrics. Advanced software analyzes this data to detect patterns or anomalies indicating the likelihood of an upcoming failure.

Unlike reactive maintenance, which responds after problems appear, predictive maintenance allows businesses to schedule repairs in advance, reducing unexpected downtime and improving fleet reliability.

Key Benefits for Fleet Operators

Reduced unplanned downtime: Early detection alerts managers to potential issues, allowing them to schedule repairs before a breakdown occurs. Vehicles stay on the road, keeping operations on track.

Lower Maintenance Costs: Smaller problems are cheaper to repair and far less expensive than having to perform major repairs later. Predictive maintenance prolongs the life of vehicle components.

Improved Safety: Real-time monitoring of critical systems helps prevent accidents due to mechanical failures, which safeguards the driver, cargo, and ultimately the business.

Better planning and scheduling: Repairs can be scheduled during off-peak hours or bundled together to minimize disruption and keep operations efficient.

Data-Driven Insights: Analytics data uncovers some trends in vehicle performance and driver behavior. Optimize routes, plan maintenance budgets, and make smarter operational decisions.

How Nigerian Businesses Can Carry out Predictive Maintenance

Even small or medium fleets can benefit from predictive maintenance, but only with the right tools and approach:

• Install sensors and telematics systems to monitor critical vehicle components.

• Real-time vehicle data collection and analyses using fleet management software.

• Train fleet managers and mechanics to interpret insights and take action proactively.

• Align the schedules of maintenance with operations to guarantee smooth workflows.

Even simple monitoring, such as checking on tire pressure or engine temperature digitally, can help avoid costly repairs and reduce downtime.

The Long-Term Effect

Companies that have adopted predictive maintenance find tangible benefits:

• Fewer emergency repairs and less downtime

• Lower total cost of ownership for vehicles

• Higher driver confidence and satisfaction

• More efficient fleet operations

• Improved customer satisfaction because of timely delivery

Predictive maintenance turns fleet management from a reactive process to a strategic advantage. The enterprises embracing data-driven solutions will be rewarded with efficiency, cost savings, and operational control.

Predictive maintenance is no longer optional for modern fleets. By investing in data-driven tools, Nigerian companies will be able to reduce breakdowns and, with decreased costs, stay competitive in fleet operations.